ABOUT US

Alnakqil-aldhabi

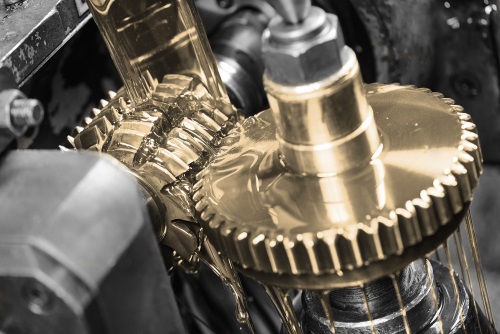

A leading company in the field of importing lubricants in Iraq is typically a specialized commercial–industrial entity that imports products such as engine oils, industrial oils, hydraulic oils, transmission fluids, and greases from international manufacturers, distributing them to the local market through a network of sales teams, warehouses, and quality-control laboratories. It focuses on well-known brands or private-label products depending on its market strategy.

How it was professionally established — Step by Step

Defining the concept and conducting market research

A group of founders (traders or petroleum/mechanical engineers) conducts a market study: demand volume, local competitors, price sensitivity, and the requirements of industrial and oil sectors.

They analyze key segments: automotive workshops, oil and gas companies, power generation plants, factories, and end consumers.

Establishing the legal entity and obtaining licenses

The company is registered commercially (LLC or joint-stock), and a general manager is appointed along with department managers (procurement, logistics, sales, and quality assurance).

Import licenses, petroleum-product storage permits, and compliance approvals from the Ministry of Trade/Oil and local authorities are obtained.

Forming agreements with global manufacturers and suppliers

Reputable suppliers (European, Asian, or American factories) are selected, and negotiations are conducted regarding pricing, minimum order quantities, and sometimes regional exclusivity.

Commercial contracts are signed with clear INCOTERMS, quality guarantees, and conditions for product return or compensation in case of defects.

Arranging financing and the supply chain

Capital is secured through partners, bank loans, or import credit lines (LC).

Shipping methods are defined—sea freight (containers/tankers) or partial shipments—along with customs-clearance coordination at Iraqi ports (such as Umm Qasr or Basra) or border points.

Investing in local infrastructure

Qualified warehouses are built or leased (protected tanks and lined containers). A filling/relabeling area may be prepared if required.

A quality-control laboratory is established or outsourced to third-party labs to test physical and chemical properties and ensure compliance with standards (API, ACEA, ISO).

Quality systems and standards

Global standards such as API (American Petroleum Institute), ACEA, or ISO are adopted.

A quality-management system (ISO 9001) is implemented, along with procedures for shipment and batch traceability.

Developing the sales and distribution network

Technical sales teams provide customers with accurate recommendations on the appropriate oil for each engine/machine.

Regional distributors, warehouses across provinces, and long-term supply contracts with oil companies and government entities are established.

After-sales services include technical consulting, mechanic training, and technical support.

Marketing and branding

Commercial marketing includes participating in industrial exhibitions, meeting with maintenance companies, and producing educational materials explaining the benefits of the products and how they reduce fuel consumption and extend equipment life.

Packaging options are offered (small bottles for workshops and large containers for factories), along with loyalty programs for distributors.

Professional factors that distinguish a leading company

Partnerships with reputable manufacturers ensure high-quality products and performance consistency.

Advanced storage and distribution facilities preserve oil properties and ensure logistics safety.

An in-house lab or certified partner lab ensures compliance and reduces customer complaints.

A professional technical and sales team capable of explaining specifications and offering customer solutions.

Compliance with regulations and transparency in invoicing and taxes, building trust with customers and authorities.

Additional services such as local filling, customer training, and preventive-maintenance programs.

Market challenges in Iraq and how a professional company handles them

Currency fluctuations and raw-material costs: Smart financial management (hedging and USD-based contracts).

Slow customs procedures: Stable relationships with professional clearance agents and pre-planned shipments.

Safe storage of flammable materials: Adhering to safety standards, employee training, and insurance.

Competition from low-quality or counterfeit products: Emphasizing quality, valid certifications, and customer education.

Demand fluctuations (oil/industrial sectors): Diversifying customer segments between civil, industrial, and oil markets.

Revenue model and growth strategy

Revenue mix: Wholesale to factories and power plants, retail to workshops, and long-term maintenance contracts.

Expansion strategy: Opening regional branches, launching a local private-label brand at competitive pricing, and offering inspection and transport services.

Sustainability: Low-emission products for modern vehicles, packaging-recycling programs, and environmental compliance.

Practical examples of daily operations

Testing every shipment upon arrival: viscosity analysis, flash point, sulfur content, and contaminant detection.

Applying FIFO (First In – First Out) inventory management to prevent product degradation.

Issuing quality certificates for each batch and providing them to customers.

Training distributors annually on the latest engine and machinery specifications.

Conclusion and customization offer

This is a detailed overview of how a leading lubricant-import company in Iraq is founded and professionally operated—from concept to execution and expansion. If you’d like, I can:

Customize this description for a specific Iraqi company (just tell me the name), or

Prepare a full Business Plan including financial projections and a logistics strategy.